Seattle-based Bouldering Project, a flourishing chain of indoor bouldering gyms with 12 locations peppered nationwide, grappled with an air quality issue as pronounced as the holds on its climbing walls. Positioned in bustling urban areas and often buzzing with climbers, Bouldering Project’s facilities dealt with a persistent challenge: managing copious amounts of airborne chalk dust while ensuring optimal indoor air quality (IAQ) for their members. The delicate particulate matter from the chalk, essential for grip but a threat to clean air filtration, posed a significant challenge, impacting not only the health and comfort of climbers but also the overall environmental sustainability of the operations.

The Staggering Cost of Clean Air Filtration

Across Bouldering Project’s diverse range of facilities, the requirement for clean air filtration translated into a single yet substantial company-wide operational demand: to identify and implement a sustainable and efficient air filtration solution. Depending on the size of the facility, the number of air filters used varied significantly. For instance, its smaller sites might use around six filters in the rooftop units (RTUs) per replacement cycle. In contrast, larger facilities, like the Springdale gym in Austin, could use upwards of 60 filters across 11 RTUs. During the peak climbing season, particularly in dry and dusty conditions, these filters were replaced as frequently as three times a week.

This high turnover of single-use disposable filters was more than just a logistical headache; it was also a financial strain. Additionally, the environmental implications were substantial. Each discarded filter contributed to the mounting waste in landfills. The sheer volume of filters used across multiple facilities meant that the Bouldering Project would contend with operational inefficiencies and an escalating environmental footprint. This continuous cycle of use and disposal highlighted the urgent need for a sustainable alternative. The company needed to rethink and resolve its air filtration financial and ecological challenges quickly.

A Sustainable Shift with K&N Washable Filters

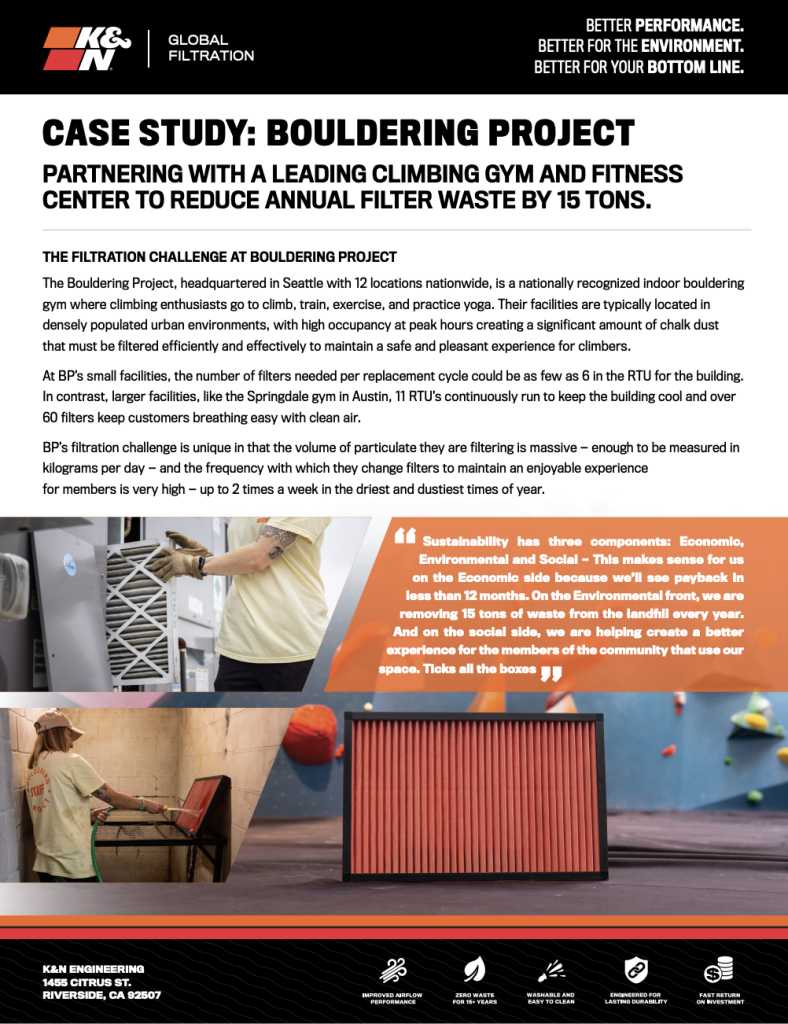

In a strategic pivot in 2024, the Bouldering Project adopted a new solution to clear the air and pave the way for more sustainable practices: K&N Global Filtration’s washable and reusable industrial air filters. After pilot testing at two of their facilities, opting to use K&N’s washable filters network-wide was a clear choice. K&N’s filters and the benefits of clean air filtration align with the Bouldering Project’s dedication to high performance — both in its clientele’s athletic rigor and the facilities’ operational standards. K&N’s filters are the only high-performance washable and reusable industrial filters on the market, uniquely capable of handling the intense demands of a busy climbing gym while significantly reducing environmental impact and operational costs. This synergy between top-tier athletic performance at the gym and the unparalleled efficiency of K&N’s clean-air filtration technology embodies a comprehensive commitment to excellence.

“Instead of constantly purchasing disposable filters, we’ve now purchased a full set of K&N reusable filters and expect to see a return on investment in less than a year. Any opportunity to re-allocate resources to create a better experience for our members, I am going to take advantage of. K&N filters were one of those opportunities.”

—Charles Morris, General Manager, Bouldering Project, Austin

K&N filters, known for their durability and effectiveness, drastically reduce the need for frequent replacements. Unlike disposable filters, K&N’s washable air filters can be reused multiple times for many years, aligning perfectly with Bouldering Project’s need for continuous air quality management without recurring costs.

The Broader Significance of the Shift to K&N Washable Filters

Bouldering Project’s nationwide implementation of K&N washable filters is proof of the tangible benefits of integrating sustainable technologies into everyday business operations for clean air filtration. This approach presents a significant opportunity for facilities worldwide that rely on single-use filters to cut operational costs and reduce environmental impact. Each reusable filter means fewer disposable filters in landfills, less waste, and reduced resource consumption for producing and transporting new filters.

The Bouldering Project case is a compelling blueprint for other facilities with similar challenges — whether in fitness or other critical industries, such as data centers, college campuses, and hospitals. It illustrates how businesses can tackle operational inefficiencies and environmental responsibilities simultaneously. As more organizations witness operational savings and sustainability benefits, the shift toward sustainable practices like washable, reusable air filters continues to gain momentum.

“Sustainability has three components: Economic, Environmental and Social. This makes sense for us on the Economic side because we’ll see payback in less than 12 months. On the environmental side, we remove 15 tons of waste from landfills every year. And on the social side, we are helping create a better experience for the members of the community that use our space. Ticks all the boxes.”

—Kaylee Wilson, National Facilities & Sustainability Manager for Bouldering Project